SOLIDWORKS PLASTICS

SOLIDWORKS PLASTICS is perfectly designed to predict and avoid manufacturing defects during the earliest stages of plastics part and injection mold design. Companies designing plastic parts can easily beneficiate this package, because it improves quality, eliminates costly mold rework, and decreases time-to-market.

- REQUEST A SOLIDWORKS QUOTE

- SCHEDULE A SOLIDWROKS DEMO

- WHAT’S NEW IN SOLIDWORKS 2019

- VIEW SOLIDWORKS SIMULATION MATRIX

SOLIDWORKS PLASTICS SOLUTIONS INCLUDES:

SOLIDWORKS Plastics Professional – for Plastics Part Designers

The most cost-effective time to optimize plastic parts for manufacturability is during the initial stages of product design. Skipping this step often leads to an inefficient mold design with an extremely narrow “good parts” processing window, resulting in high reject rates and time-to-market delays.

- CAD Integrated

SolidWorks Plastics helps ensure molds will workright the first time to avoid multiple rounds of time-consuming, costly, andunnecessary rework.

- Easy To Learn And Use

Takes only minutes to learn and does not require extensive analysis or plas

- Facilitates Design Team Communication

web-based HTML reports make it fast and easy to communicate simulation results and design advice to all members of the design-to-manufacturing team

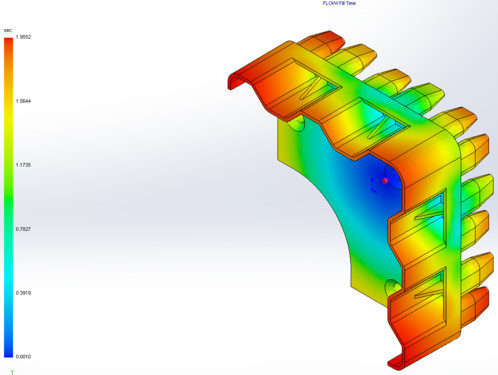

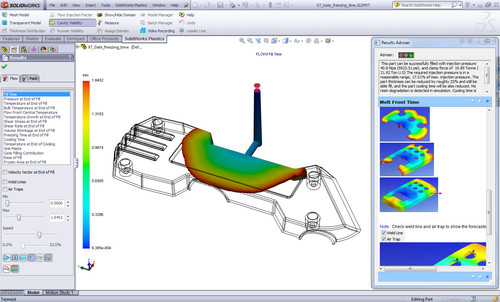

SOLIDWORKS Plastics Premium – for Mold Designers and Mold Makers

SolidWorks Plastics Premium gives anyone who designs or builds injection moldsan accurate, easy-to-use way to optimize them. You can quickly create andanalyze single, multi-cavity, and family mold layouts, including sprues, runners,and gates. You can even balance runner systems and estimate cycle time, clamp tonnage, and shot size.

- Avoid Costly Mold Rework

SolidWorks Plastics helps ensure molds will work right the first time to avoid multiple rounds of time-consuming, costly, andunnecessary rework. - Easy To Learn And Use

analyze sprues, runners, and gates to balance runner systems; optimize gate type, size, and location; determine the best runner layout, size, and cross-sectional shape. - Facilitates Design Team Communication

enables mold designersand mold makers to quote tooling projects quickly and accurately; assists manufacturing teams to size the injection molding machine for a given mold,optimize injection molding cycle time, and reduce plastics material scrap

SOLIDWORKS Plastics Standard – for part designers

For plastic part designers, the Standard edition is very helpful because it enables them to optimize parts for manufacturability in the early stages of design. You can analyze and modify designs at the same time you optimize for form, fit, and function all because the SOLIDWORKS Plastics Standard is fully embedded within the SOLIDWORKS CAD.