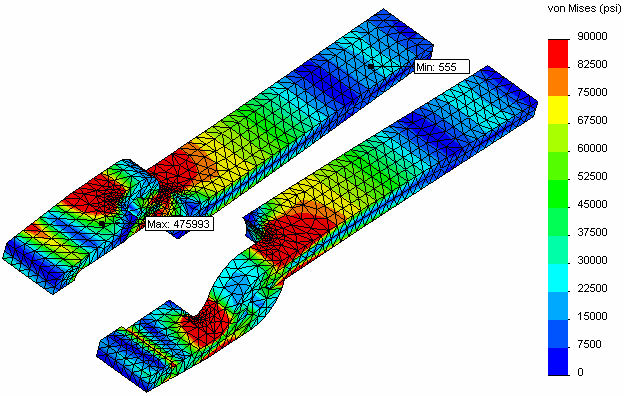

SOLIDWORKS SIMULATION PROFESSIONAL

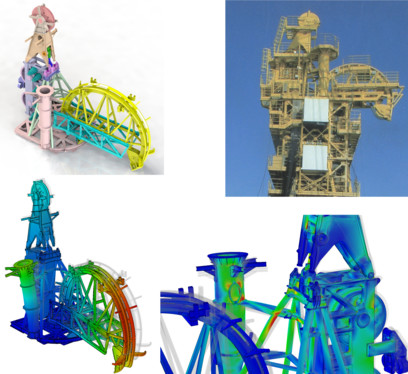

SOLIDWORKS Simulation Professional delivers easy-to-use, powerful capabilities to carry out sequential multi-physics. Temperature distributions from a static or transient thermal analysis can included into a linear static analysis allowing for the effects of material thermal expansion in the stress calculations. For products that experience vibration in their working environment, a frequency analysis will determine the product’s natural modes of vibration to limit the possibility of resonance which can dramatically shorten component life.

Key Capabilities

- Linear Static Simulation

- Timed based mechanism motion simulation

- Fatigue Simulation

- Structural Optimization

- Frequency Simulation

- Vibration Simulation

- Buckling Simulation

- Structural Thermal Simulation

- Drop Test Simulation

- Pressure Vessel Design Simulation

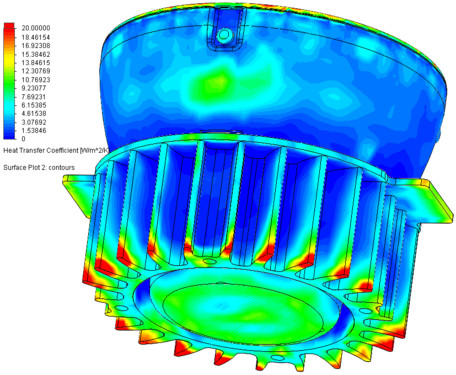

SOLIDWORKS FLOW SIMULATION Solutions Include

- Evaluate forces and stresses between contacting parts, including friction

- Apply bearing loads, forces, pressures, and torques

- Optimize designs based on structure, motion, or geometry

- Use connectors or virtual fasteners to model bolts, pins, springs, and bearings

- Activate the Trend Tracker and Design Insight plots to highlight optimal design changes while you work

- Evaluate complex problems early in the design cycle with plane stress, plane strain, and axisymmetric linear static analysis

Understand the effects of temperature changes on parts and assemblies

- Study conduction, convection, and radiation heat transfer

- Utilize isotropic, orthotropic, and temperature-dependent material properties

- Determine thermal stresses due to temperature distributions and varying materials

Analyze assembly motion for process and task workflow with event–based simulation

- Define motion studies based on model event and assembly actions

- Trigger actions through new motion sensors, time, or the completion of a previous task

- Evaluate characteristics like actuator force and joint loads for motion optimization

- Gain greater control of model actuators with servo motors

Study the effects of cyclic loading on product life

- Check a system’s expected life or accumulated damage after a specified number of cycles

- Import load history data from real physical tests to define loading events

Simulate vibration or buckling in your designs

- Examine how vibrating or unstable modes can shorten equipment life and cause unexpected failures

- Assess the effects of load stiffening on frequency and buckling response