SOLIDWORKS CAM PROFESSIONAL

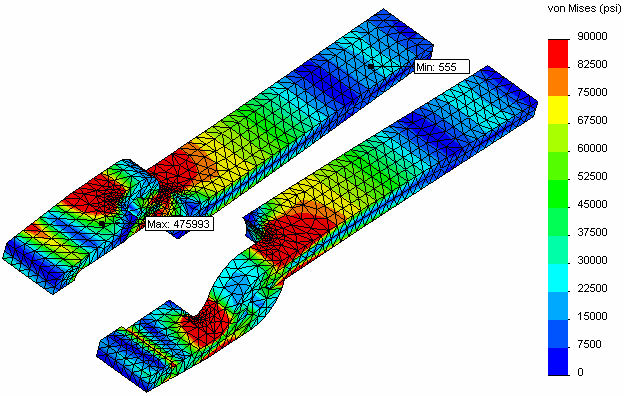

SOLIDWORKS CAM uses rules-based machining to enhance the programming process in the same way rules-based design helped to speed up the drawing and design process. Rules-based machining leverages tolerances that have been assigned to each component, allowing users to focus on the critical areas of making a part rather than touching every feature that needs to be machined. With SOLIDWORKS CAM, you will be able to enhance your manufacturing process by capturing company standards, speed up quoting, and test manufacturability of a design earlier in the process.

Key Capabilities

- Rules-based machining

- Tolerance-Based Machining

- Feature Recognition

- Easy visualization of fixtures and tooling

- Toolpath Simulation within SOLIDWORKS CAM

- REQUEST A SOLIDWORKS QUOTE

- SCHEDULE A SOLIDWROKS DEMO

- WHAT’S NEW IN SOLIDWORKS 2018

- VIEW SOLIDWORKS CAM MATRIX

SOLIDWORKS CAM PROFESSIONAL Solutions Include:

SOLIDWORKS CAM Professional builds on the capabilities of SOLIDWORKS CAM Standard to increase programming capabilities. SOLIDWORKS CAM Professional adds the following functionality:

The use of knowledge-based machining and tolerance-based machining allows for:

Assembly Machining: Users who are looking to design fixturing or machine a group of parts can create the tables, vises, clamps, or any other holding mechanisms using a SOLIDWORKS assembly.

Turning: SOLIDWORKS CAM will support single turret turning inside the SOLIDWORKS part environment. Similar to part milling, users can take advantage of Automatic Feature Recognition, Knowledge-Based Machining, and configurations.

3+2 Milling: Programmers can take advantage of 4- and 5-axis machining centers with SOLIDWORKS CAM Professional.

High-Speed Machining: SOLIDWORKS CAM Professional utilizes VoluMill 2.5-axis milling routines from Celeritive™ Technologies. The advantages of using these machining strategies are

- Up to 75% savings on cutting tool costs.

- 50% to 80% reductions in machining cycle times.

- Easy-to-learn machining strategies

- No special machine tools are required

- Reduced wear and tear on your equipment due to smoother transitions in toolpaths