Engineering & Technology Consulting Services

FEA Training Consultants Inc. supplies engineering and technology consulting services for manufacturing firms to assist in their product development process. Our goal is to act as a seamless extension of your company’s engineering department and help you to make your product design and manufacturing process safe and efficient.

Our Services Include

- Health and Safety assessment reports

- Macro development (coding) for 3D Design automation

- Software engineering (software testing, design, and software requirements specification)

- Engineering process development, programming, and algorithms

- Integrate Machine Learning and AI technology in the Product Development Process

- Product design & development using CAD & analysis tools

- Finite Element Analysis for design validation and optimization

- Computational Fluid Dynamics for fluid flow modeling and macro programming for automating analysis

- Programming and coding to automate rigid body dynamic analysis (kinematics & force calculations)

FEA Training Consultants Inc. – PRODUCT DESIGN AND DEVELOPMENT GROUP

As part of FEA Consultants full service Design Engineering Team based in Mississauga, Ontario, the Product Design and Development Group is involved in some of the most demanding product design and simulation projects in industry today. Supported by FEA Consultants long history of product design, manufacturing & simulation expertise and collection of industry professionals, the Product Design and Development Group is capable of handling the most demanding engineering projects including custom coding, programming and integrating machine learning / AI technology for robust product development.

We provide FEA consulting services to companies located within USA and Canada. Request a quote or contact us by email info@fea-tc.com or call us at 905-990-0094 for more information.

Additional Engineering Consulting Services Offered

- Health and safety consulting services that protect workers, reduce employer liability, and ensure compliance with safety regulations

- Integrating health and safety systems, focusing on HVAC ventilation systems, machine guarding, lifting devices, etc.

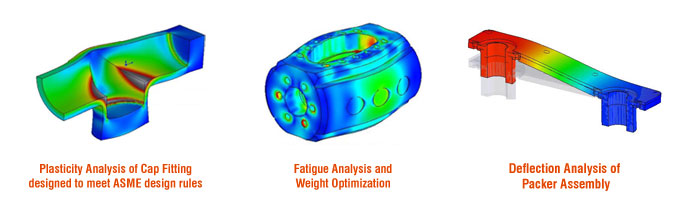

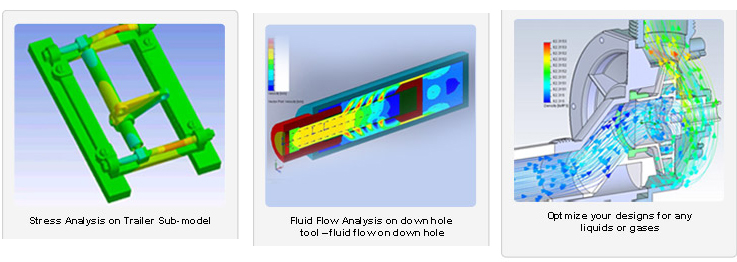

- Structural stress, safety factor and vibration analysis on different mechanical designs

- Non-linear stress analysis (material plasticity, large deformation and contact)

- Steady state and transient heat transfer analysis on electronic and mechanical components

- Fatigue, buckling and structural dynamic analysis

- Fluid Flow Analysis to predict and eliminate design problems such as high pressure drop, erosion and cavitation on hardware designs used in power, water treatment and oil & gas Industry

- Fluid structure interaction analysis

- Design simulation to check compliance to design authority requirements (Example – ASME)

- Pressure drops, velocity distribution, particle tracking, fluid structure interaction and conjugate heat transfer analysis

- FEA and CFD software sales, training and mentoring services.

Some of our completed projects

- Macro development (coding) for 3D Design automation

- Software engineering (software testing, design, and software requirements specification)

- Programming and coding to automate rigid body dynamic analysis (kinematics & force calculations)

- Stress Analysis of Ball valve to evaluate contact stress using non-uniform pressure loading (Valve Industry)

- Thermal and Stress Analysis of Heat- Exchanger assembly using ASME design by analysis guidelines

- Detailed analysis of Pressure Vessels components using alternate rules for boiler and pressure vessel design (ASME Sec VIII Division 2) (Pressure Vessel Industry)

- Detailed Analysis of nozzle assembly for external pipe loading and thermal loading using stress linearization method per ASME Sec VIII Division 2 (Pressure Vessel)

- Detailed PSD Random Vibration of electronics PCB assembly (Electronics)

- Shape optimisation and motion simulation of automated machinery (evaluated parameters also include velocity, acceleration, force distribution, stress deflection etc.) (Automotive)

- Durability Analysis of automotive suspension assembly to evaluate fatigue life due to cyclic loads. (Automotive)

- Drop test simulation to evaluate the structural durability on various consumer products such as cell phones, electronic box etc. (Electronics Industry)

- Pressure Drop Calculation on screen assembly used in water purification (Water Purification Industry)

- Simulating severe accident scenario in a nuclear reactor to evaluate the plastics response of the system. (Nuclear Industry)

- Structural Analysis on various medical equipment to evaluate stress, deflection and safety factor. (Medical Industry)

- CFD Analysis to evaluate on automotive body to evaluate the induced drag and lift forces. (Automotive)

- Completed Fluid-Structure Interaction Analysis to simulate the transient time dependant response of an internal flow assembly with special orifice plate design. (Oil and gas industry)

- Non-Newtonian flow simulation to evaluate the pressure drop induced across the mold. (Tool and die industry)

- Dynamic non-linear analysis to evaluate the stability of trailer assembly. (Automotive Industry)

- Erosion analysis to evaluate erosion rate density and cavitation analysis on oil and gas equipment. (Oil & Gas Industry)

Samples Of Our Work